PFAS, known as “forever chemicals,” can be harmful to our drinking water. Regular water monitoring protects public health and ensures PFAS compliance.

What Are PFAS?

PFAS (per- and polyfluoroalkyl substances) — including PFOA, PFOS, and GenX — are persistent chemicals found in industrial and consumer products such as firefighting foam, water repellent items, and cookware. Released into the environment, they accumulate in rivers, lakes, and groundwater, posing serious health risks — making PFAS compliance an important topic for our communities.

Are PFAS Harmful To Humans?

PFAS, known as “forever chemicals,” do not break down easily and build up, or bioaccumulate, in the environment and human body. Scientists have identified ingestion through drinking water as the primary pathway for exposure in humans. PFAS have been linked to liver and kidney damage, hormone disruption, reproductive issues, and certain cancers.

Understanding “Forever Chemicals” in North Carolina

1980s: PFAS have been present in NC since the 1980s, largely due to industrial discharge into waterways such as the Cape Fear, Catawba, and Broad Rivers — the drinking water source for tens of thousands of North Carolinians.

2017: Public concern rises after GenX was detected in the Cape Fear River.

2024 (April): EPA finalizes national standards for 6 PFAS compounds in drinking water (PFOA, PFOS, PFNA, PFHxS, PFBS, HFPO-DA), giving public water systems 5 years to comply.

2024: An EWG analysis finds that the drinking water for at least 2.5 million North Carolinians exceeds the just-finalized federal limits.

2025: The NC DEQ states its intent to draft a rule requiring industrial dischargers and POTWs to monitor and report on levels for 3 PFAS chemicals — PFOA, PFOS, and GenX — to attempt to reduce discharge at the source and lower the burden on residents and municipalities.

2029: All public water systems must be in compliance with the EPA’s new national standards, the PFAS maximum contaminant levels (MCLs).

Move Towards Compliance – Conducting a PFAS Pilot Study

Thrasher’s team of water resources experts is up-to-date on the latest developments in the industry, from regulations to water treatment solutions.

Our water resource engineers recommend that municipalities take the following steps and use a pilot study to determine the best path forward for PFAS compliance. Our team has vetted suppliers and is already working with them to complete these studies and can help manage the process from start to finish.

Step 1: Source Water Identification

- Identify primary intakes: rivers, lakes, wells

Step 2: Test Source Water

- Measure water quality to determine direction for Pilot Study

Step 3: Results Interpretations

- Compare to Federal MCLs

- Assess Hazard Index for mixed PFAS Chemicals

Step 4: Conduct A Pilot Study

- Understand the type of material or resin treatment options available

- Granulated Activated Carbon

- Ion Exchange

- Reverse Osmosis

- Conduct study to verify which treatment options

are most effective at eliminating unwanted material

Step 5: Existing Treatment Process Update

- Based on results, design necessary upgrades to existing facilities to remove PFAS chemicals from drinking water source

- Perform the changes to the water treatment process, including updating filters, new resin treatments, and any other retrofitted specialized equipment

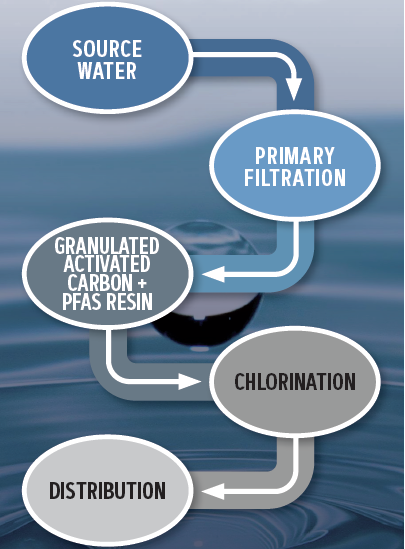

Water Treatment

Pilot testing ensures selection of the most effective treatment. Upgrades may include retrofitting existing treatment or expansion with new treatment. Regular monitoring protects public health and ensures PFAS compliance.

Have Questions? Thrasher NC Can Help.

Our experienced utilities engineers can help navigate you water system needs. Contact us whenever you have questions.